Ensuring safety and airworthiness is of paramount concern in any aviation operation. With aircraft fleets comprising millions of intricately designed parts working in seamless coordination, maintaining these complex machines to stringent standards is an immense responsibility. Left unchecked, even minor defects could potentially jeopardize flights with catastrophic consequences.

Which is why dedicated programs focused on comprehensive aircraft Maintenance, Repair and Overhaul (MRO) play such a defining role within commercial, private and general aviation alike. Beyond routine checks, scheduled MRO cycles conducted by specialized technicians help systematically preserve each certified component and system as intended by manufacturers.

Today, we explore the critical nature of MRO services in the aviation industry. From their specialized scope pegged to aviation authority protocols, to benefits regarding compliance, efficiency and cost optimization over aircraft operational lifespans. We will also discuss the important role MRO fulfills for responsible operators aiming to successfully manage sizable aviation operations safely and economically for decades to come.

What Is MRO In Aviation?

MRO stands for Maintenance, Repair, and Overhaul–a term that refers to a higher order of aircraft maintenance beyond routine upkeep. Where general maintenance handles daily checks and minor repairs, MRO is governed by stringent protocols established by aviation regulatory authorities and manufacturers, with certifying agencies like EASA and FAA providing oversight.

MRO involves planned aviation maintenance programs where skilled technicians within ISO and OEM-approved MRO facilities conduct scheduled deep-dive checks to restore every detailed system and component to certified configurations using specialized tooling and equipment. Rigorous record-keeping requirements are in place to demonstrate strict adherence to specifications. This differentiated approach plays a pivotal role in sustaining safety and compliance levels demanded within commercial and private aviation.

MRO approach stands apart from general maintenance which may neglect systematic performance verification over time. MRO programs instead proactively identify defects through rigorous Checks and scheduled component inspection/replacement. They reinforce adherence to original airworthiness standards vital for operational certificate approval.

By participating in MRO, operators and owners empower qualified personnel to dedicate sufficient time to evaluating aircraft conditions holistically. This helps safeguard compliant airworthiness that routine maintenance alone can fail to sustain in aviation’s complex operating environments over prolonged service lifetimes. Moreover, MRO plays an integral role in ensuring the safety of aircraft for conscientious fleet managers, reinforcing their commitment to maintaining the highest standards of safety and reliability in aviation operations.

Importance of MRO in Aviation

Safety

Scheduled MRO work performed at prescribed phase-check intervals helps proactively identify defects before they can develop into serious issues. Dedicated technicians have ample time and resources to conduct thorough inspections, repairs, and testing to restore certified airworthiness without compromising quality, a key success factor in aviation’s safety-critical environment. Furthermore, this meticulous approach ensures that all necessary measures are taken to maintain the highest standards of safety and reliability in aviation operations.

Compliance

Following manufacturers’ planned MRO procedures at all times certifies the aircraft’s continued satisfaction with original airworthiness standards set by regulatory authorities. This is important not just for maintaining valid operating certificates but also for meeting standards expected by customers and insurers. Non-compliance can negatively impact resale values and marketability.

Efficiency

Rather than risk degraded performance and reliability from deferred maintenance over time, planned MRO through preventative upkeep helps maintain predictable operational costs. Programmed component overhauls and repairs extend intervals between base checks, minimizing aircraft downtime and disruption to flight schedules.

Cost Effectiveness

While initial investments in specialized tooling, equipment, and technician training for MRO services are substantial, the approach results in huge payoffs long-term by avoiding costly field fixes or premature fleet retirements. It helps private jet owners and operators optimize whole-life ownership costs.

Reliability

By restoring certified configuration integrity as prescribed, MRO upgrades fleet dispatch reliability margins. Consequently, this strengthens schedule adherence, which is critical for customer service levels within commercial operations or VIP charters requiring mission-critical performance.

Resale Prospects

Demonstrating documented MRO program conformity proves airworthiness pursued by prior owners to buyers and financiers – a key enabler potentially improving residual values for trade-ins or end-of-lease asset remarketing initiatives. Therefore, ensuring adherence to MRO program standards can enhance the marketability and value of aircraft assets in various transactions.

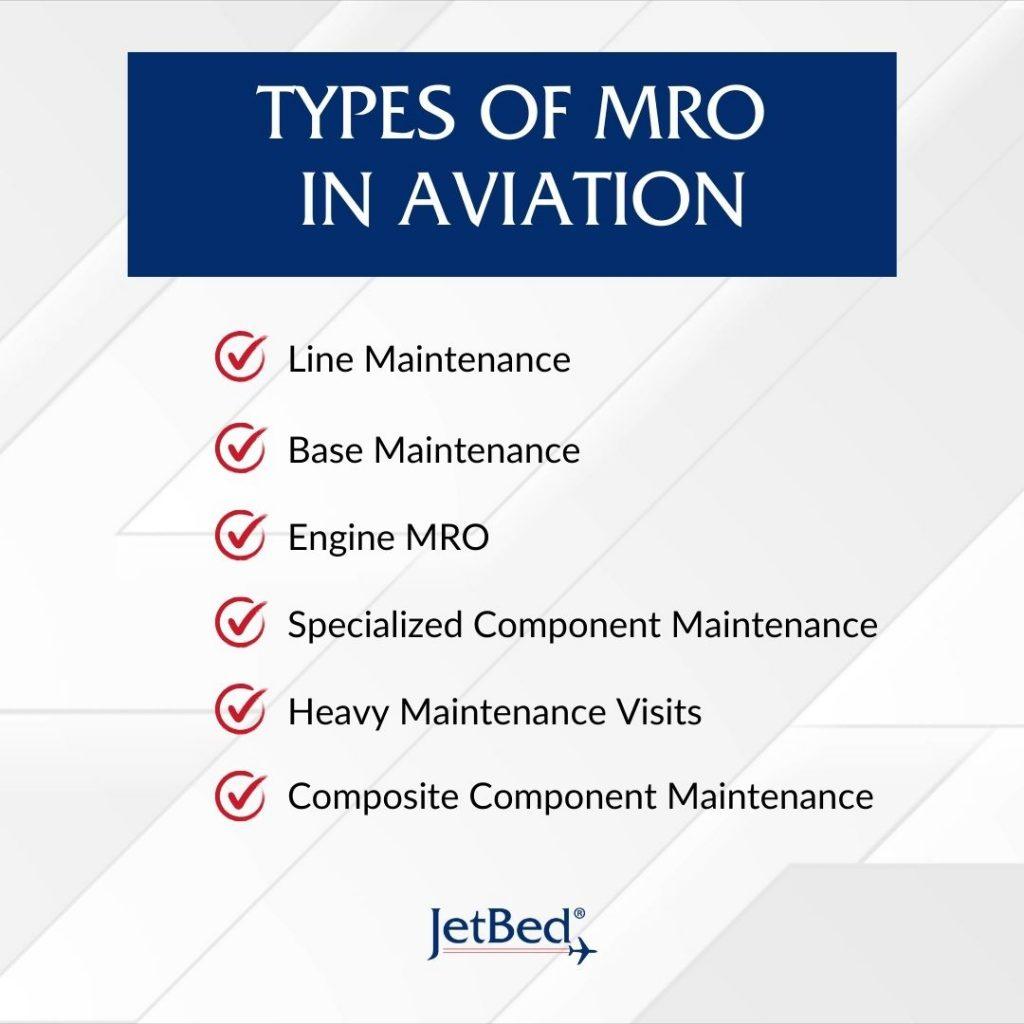

Types of MRO in Aviation

Line Maintenance

Performed efficiently by technicians at airports, line maintenance encompasses daily inspections, minor defect rectification, and quick aircraft turnovers critical for any commercial operator’s schedule reliability and On-Time Performance. Moreover, timely and effective line maintenance operations are essential for ensuring smooth and efficient flight operations, minimizing disruptions, and meeting passengers’ expectations.

Base Maintenance

Deeper checking of airframes and interiors combined with systems evaluations and role-specific component overhauls at Phase-checks. This robust element of MRO restoration is formative for all aircraft types’ ongoing certification undertaken by authorized repair stations. Furthermore, Phase-checks play a crucial role in maintaining the airworthiness and regulatory compliance of aircraft, ensuring safe and reliable operation throughout their service life.

Engine MRO

Specialized requirements include component repair/replacement and established hot section inspection intervals integral to power plant dependability over thousands of operating hours. These are commonly handled at OEM-tied service centers. Moreover, adherence to these requirements is essential for ensuring the long-term reliability and performance of aircraft engines, which are critical components for safe and efficient flight operations.

Specialized Component Maintenance

From advanced avionics units to mission systems, dedicated workshops with certification and OEM partnerships undertake MRO to sustain certified functionality essential across industry segments including regional, charter, and private aviation.

Heavy Maintenance Visits

For certain airframes, particularly longtime operations, extensive HMV checking may be required where Strip and Repaint activities are performed alongside comprehensive inspections by Principal MRO Providers maintaining extensive part holdings.

Composite Component Maintenance

With new aircraft relying extensively on advanced materials, associated MRO techniques and approvals have evolved to ensure structural integrity safety case requirements stipulated by regulatory authorities are comprehensively satisfied. Consequently, advancements in MRO practices are essential for meeting stringent safety standards and ensuring the airworthiness of modern aircraft.

MRO plays a defining role for conscientious fleet managers and will continue prominent recognition within the aviation sector globally.

In conclusion, it is clear that MRO serves as the backbone of modern aviation safety, compliance, and efficiency standards. Beyond routine maintenance tasks, dedicated specialists conducting scheduled MRO ensure airworthiness is systematically preserved through each certified component and system as aircraft progress through long service lives.

Through specialized tooling, facilities, skill sets, processes, and regulatory oversight discussed here and in our past article on “Importance of Tool Control in Aviation”, MRO sustains airworthiness with a comprehensive, preventative approach. This mitigates risks of performance degradation or unplanned costs stemming from deferred defects. With such evident benefits, the MRO industry continues to gain prominence globally within commercial and private aviation sectors alike. Furthermore, the ongoing adoption of proactive maintenance strategies underscores the industry’s commitment to ensuring the safety, reliability, and efficiency of aircraft operations.

Now that you’re familiar with what MRO means in aviation, ensure you get yourself a JetBed for your travels. It’s light, easy to store and use, but most importantly they are exceedingly comfortable. It’s sure to make every minute spent in the air feel like you’re right at home.

For more information on aviation protocols, safety operations, aviation trends, and so on, kindly check our blog.